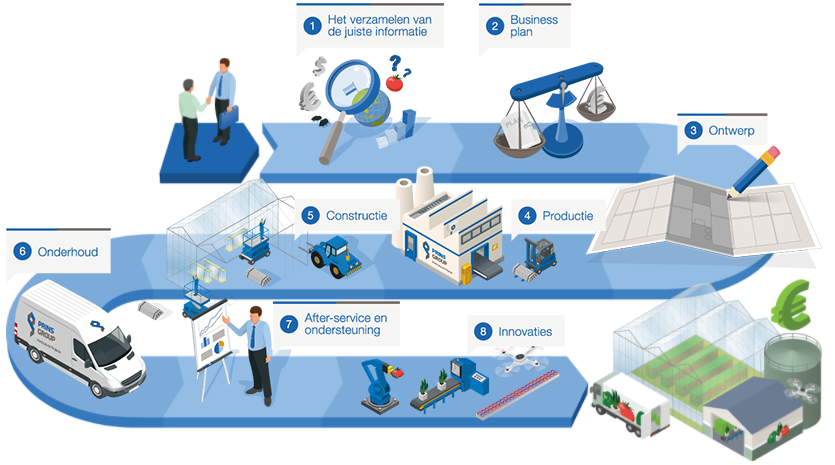

The total growing solution

Prins Group over the world

Choose the continent and find out more projects

Featured projects

Project Querétaro 2 – Mexico

m2

240000

Tomaat

Early 2021 we start with a new high tech greenhouse project of 24 hectares in the neighborhood of Querétaro. Project video: click here

Find out moreHorti Prins Service (HPS) provides varies bespoke solutions to both local and international investors for greenhouse industry.

Contact

We'd love to hear from you ! Leave a message below and we will get in touch with you shortly.